Test your Product’s Behavior.

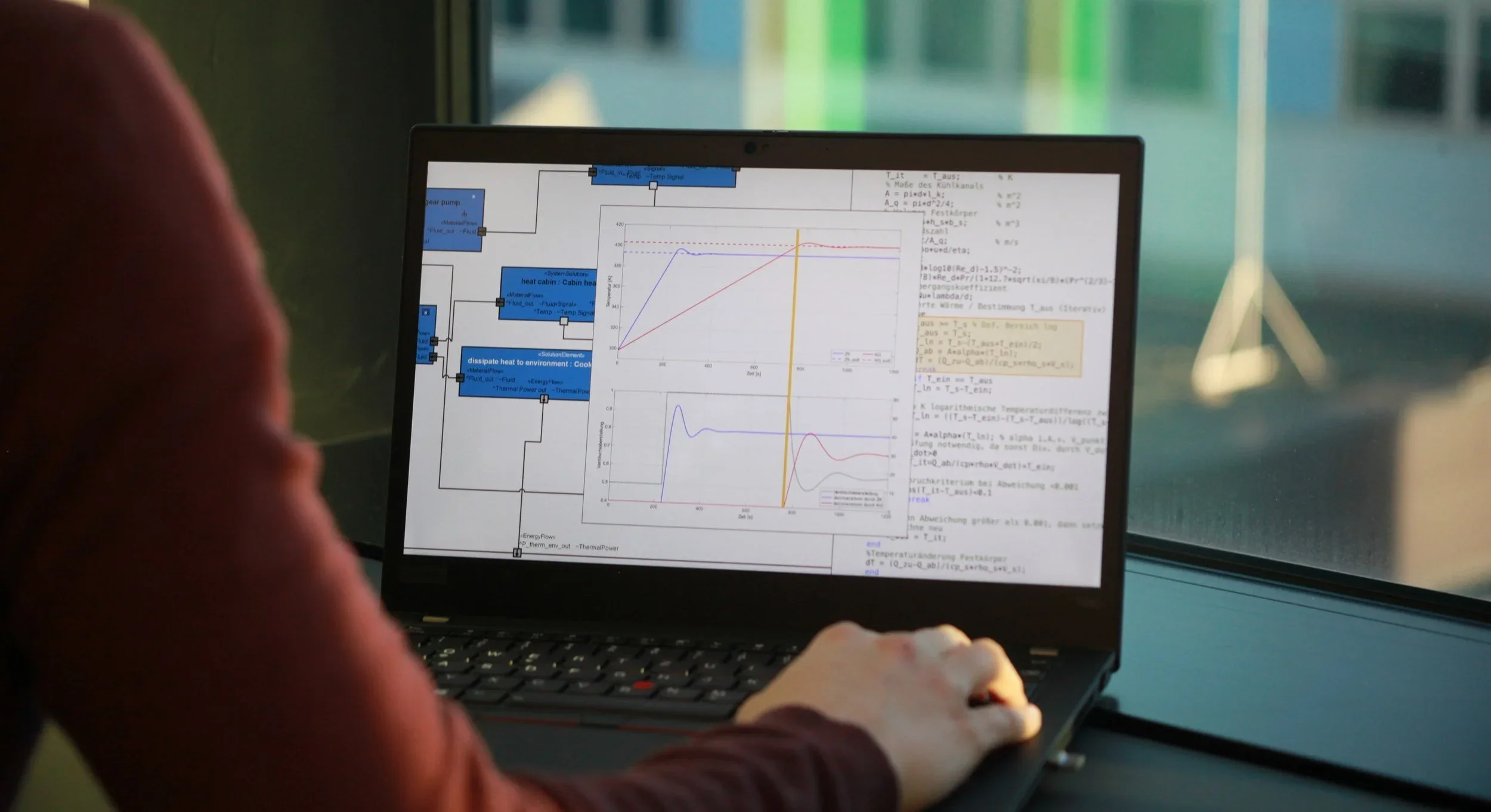

The system model executes interlinked physical behavior models to verify requirements across functions and solutions. This makes performance, reliability, and compliance continuously measurable from the first iterations and throughout product development.

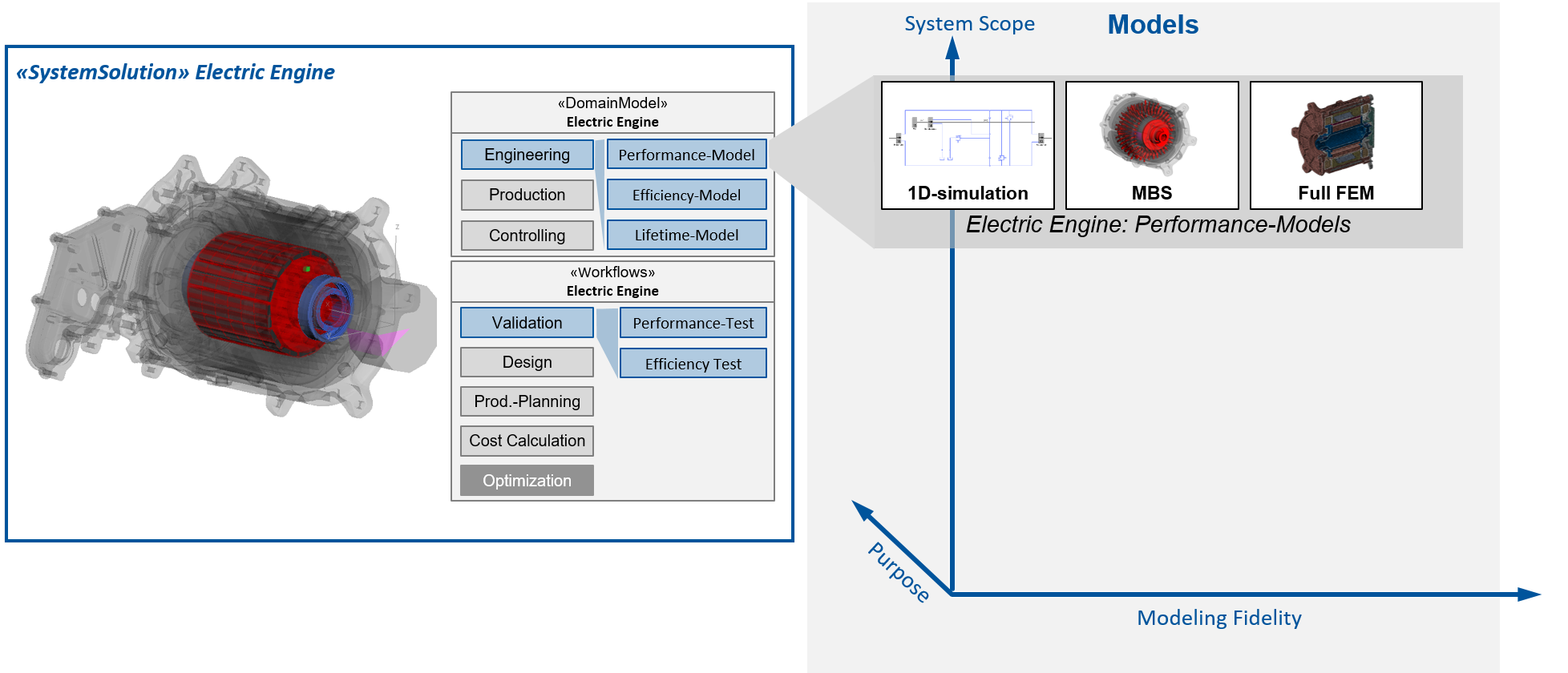

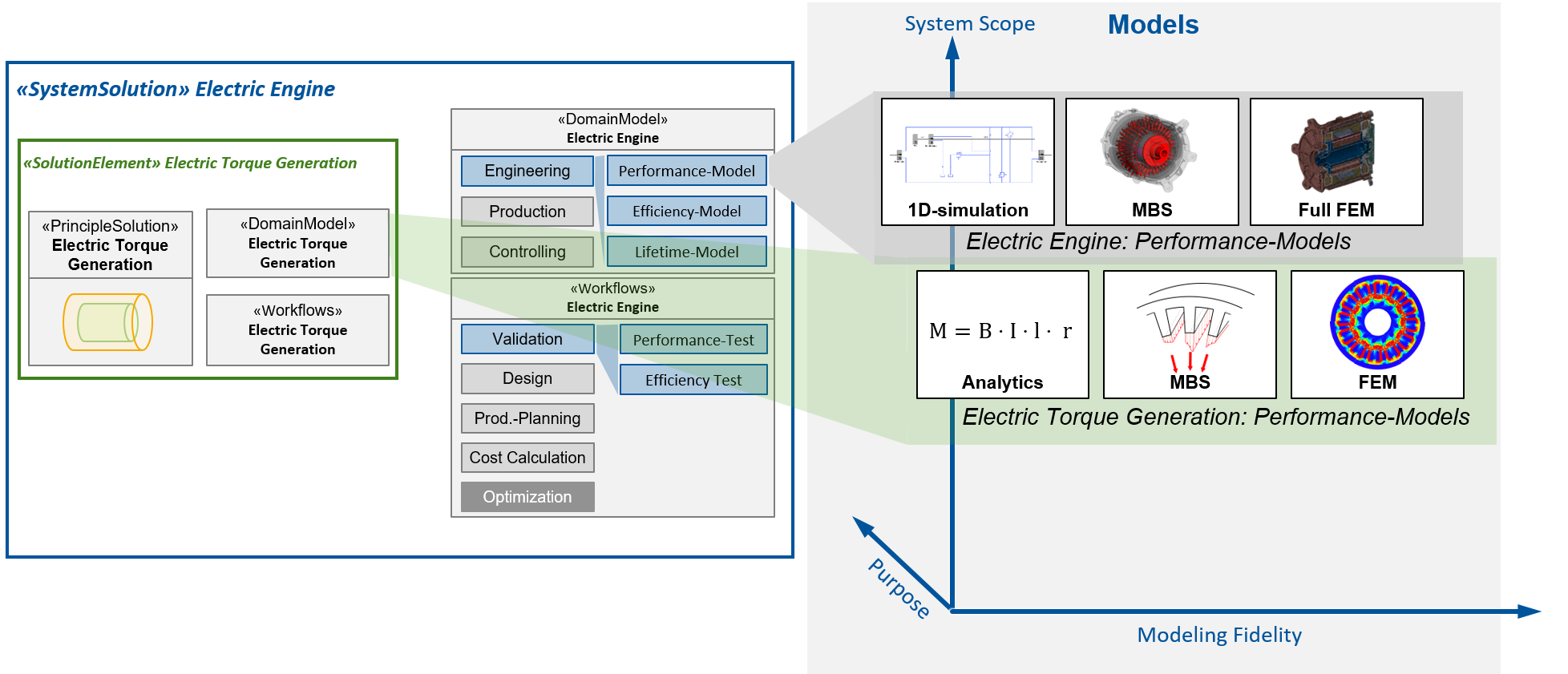

Testing product behavior can be complex. In motego, domain models are integrated into Solution Elements and System Solutions through a clear classification by purpose, scope, and fidelity. At the contact level a Solution Element combines a principle solution, its domain models, and the workflows. At the higher level a System Solution assembles the relevant elements and their own domain models, then runs workflows for requirements verification or optimization. This approach is illustrated with an example system solution: “Electric Engine”.

Moreover, models are grouped for Engineering, Production, and Controlling. Engineering includes performance, efficiency, and lifetime models. Production focuses on manufacturing models. Controlling applies cost models. Validation workflows run performance or efficiency tests, and additional workflows cover production planning, cost calculation, and optimization. All artifacts remain linked to requirements, functions, and solutions for early, repeatable, and traceable verification.

System Solution: Electric Engine

The SystemSolution “Electric Engine” organizes domain models and executable workflows within the system model. For performance evaluation the workflow selects 1D simulation for rapid studies, an MBS model for system dynamics, or a full FEM model for detailed physics. Parameters transfer automatically and results are recorded for consistent reuse from concept to detailed design.

Solution Element: Electric Torque Generation

The system solution includes the Solution Element “Electric Torque Generation,” which realizes the function of generating torque in the air gap. It bundles the principle solution, its domain models, and the executable workflows so Engineering, Production, and Controlling can access the same assets. For performance evaluation the model chain progresses from analytic torque sizing to multibody dynamics and losses, and then to electromagnetic FEM for field distribution and torque ripple.

System Solution: Rolling Bearing

Alongside torque generation, the system solution embeds a “Rolling Bearing” SystemSolution. For performance evaluation this scope uses models that progress from rigid to full kinematic to full contact.

System Solution: Workflow

Multiple workflows validate system behavior. In a performance test, electromagnetic FEM provides actuation characteristics and loss maps, and the rolling-bearing model provides mechanical losses and bearing kinematics. The engine-level MBS combines these with the inverter and thermal networks to compute key performance indicators such as the efficiency map, power capability, energy over cycles, and durability, while preserving traceable links to all source models.

motegoPlugin

Learning and applying model-based systems engineering methods is challenging. With our motego plugin we strive to make the first model-based systems engineering experience as well as entire change processes as easy as possible.

Explore the future of digital product development with us!